Retail Inventory Management: The Hidden Costs of Manual Counting vs. RFID Automation

Table of Contents:

- The Scale of the Retail Inventory Problem

- Why Manual Inventory Management Fails

- The Hidden Costs of Poor Inventory Management

- What Modern Retail Inventory Management Looks Like

- RFID Technology is Finally Accessible

- Making the Transition

- The Cost of Staying Behind

- Your Next Step

Nobody talks about it at industry conferences. It doesn’t make it into the trade publications. But every retailer knows the uncomfortable truth: while other industries have modernized their operations, retail inventory management systems are still operating the same way we did 20 years ago.

Walk into most retail operations today and you’ll find a familiar scene. Staff with clipboards and printed spreadsheets, manually counting products one by one. Calculators, pencils, and the occasional barcode scanner that takes longer to use than just writing things down. It’s 2025, and retail inventory tracking is still operating like it’s 1995.

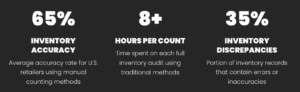

KEY INSIGHT: The average U.S. retailer maintains only 65% inventory accuracy – meaning more than one-third of what they think they have in stock is incorrect.

The Scale of the Retail Inventory Problem

The numbers tell a sobering story about inventory management challenges. According to industry research, the average U.S. retailer maintains only 65% inventory accuracy. That means more than one-third of what they think they have in stock is incorrect. For every three items a customer wants to buy, at least one might not actually be available despite what their inventory management software says.

This isn’t just a small business problem. We’ve worked with established retailers doing millions in annual revenue who still dedicate entire weekends to manual stock counting. Golf pro shops with $500,000 in inventory spending 8+ hours with teams of people just to get a snapshot of what they own. Jewelry stores closing early monthly to count their pieces by hand. Boutiques pulling their best sales staff off the floor to hunt through stockrooms with inventory spreadsheets.

The irony is striking. These same retailers have embraced technology everywhere else. They accept credit cards through sophisticated POS systems. They run targeted social media campaigns. They analyze customer data to improve their marketing. But when it comes to retail inventory control and knowing what products they actually have to sell, they’re using methods their grandparents would recognize.

Why Manual Inventory Management Fails Modern Retail

Manual inventory management isn’t just inefficient. It’s actively harmful to modern retail operations. Here’s why traditional inventory tracking methods fail:

Inventory Shrinkage and Human Error

Even the most careful employee makes mistakes during inventory audits. Items get miscounted, SKUs get confused, and data entry errors compound over time. When you’re dealing with thousands of products across multiple categories, perfect inventory accuracy is impossible with manual methods.

Labor Costs and Time Management

Every hour your staff spends on inventory counts is an hour they’re not helping customers, processing orders, or growing your business. If you’re paying three employees $20/hour for an 8-hour inventory audit, that’s $480 just in labor costs. Add the opportunity cost of what those employees could have been doing instead, and the real cost of manual inventory management triples.

COST REALITY CHECK: Manual inventory counting costs retailers an average of $1,440 per audit when you factor in opportunity costs.

Real-Time Inventory Data Becomes Obsolete

That weekend inventory audit you just completed? It’s already wrong. Every sale, every return, every product that gets moved changes your actual stock levels. By the time you finish your physical inventory count, you’re already operating on outdated information.

Customer Experience and Inventory Visibility

Nothing damages customer confidence like being told “we should have that in stock” only to discover you don’t. Modern consumers expect retailers to know what they have available in real-time. When you can’t deliver on that basic expectation of accurate inventory levels, you lose credibility and sales.

Inventory Forecasting and Business Intelligence

Without accurate, real-time inventory data, every business decision becomes a guess. How much should you reorder? What’s actually selling well? Which items are sitting too long? Manual stock counting gives you snapshots, but modern retail business moves at the speed of real-time inventory tracking.

The Hidden Costs of Poor Inventory Management

Most retailers focus on the obvious costs of manual inventory: the labor hours and the time investment. But the hidden costs of poor inventory control often dwarf these visible expenses.

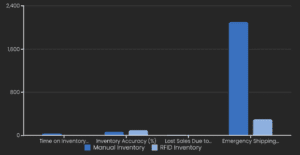

The chart above illustrates the performance gap between retailers using manual inventory methods versus those who have implemented RFID technology. This gap represents not just operational differences but real financial implications that affect bottom-line performance year after year.

Lost Sales from Stock-Outs and Inventory Discrepancies

When your inventory management system shows you have something in stock but you don’t, you lose that sale. Worse, you often lose the customer’s trust. They’ll go elsewhere and might not come back.

Overstock from Poor Inventory Visibility

Without real-time inventory tracking, retailers often order more than they need “just to be safe.” This ties up capital in slow-moving inventory and reduces cash flow for better investments.

Emergency Shipping and Inventory Replenishment Costs

When you discover you’re out of a popular item at the last minute due to poor inventory control, you end up paying premium shipping costs to restock quickly. These emergency orders are often 2-3x more expensive than planned purchases.

Staff Productivity and Time Allocation

Your best salespeople shouldn’t be conducting inventory audits in the back room. Every hour they spend on manual inventory tasks is an hour they’re not generating revenue on the sales floor or improving customer service.

Inventory Shrinkage and Loss Prevention

Manual inventory counting makes it nearly impossible to identify theft, damage, or loss quickly. Items disappear gradually, and by the time you notice during your next physical inventory count, it’s too late to investigate or take corrective action.

BOTTOM LINE: These hidden costs often exceed visible labor costs by 300-500%.

What Modern Retail Inventory Management Looks Like

The contrast with modern automated inventory systems is stark. Retailers who have embraced RFID inventory management and automated tracking operate in a completely different reality.

Real-Time Inventory Visibility

They know exactly what they have in stock at any moment with real-time inventory tracking. No guessing, no estimates, no “let me check the back room” conversations with customers.

Automated Inventory Updates

When a product sells, the inventory count updates immediately in their inventory management software. When new shipments arrive, they’re logged into the system as they’re received. The inventory data is always current.

Automated Reorder Points and Inventory Replenishment

Inventory management systems can be configured to automatically reorder products when they hit predetermined levels. No more emergency orders or surprise stock-outs due to poor inventory tracking.

RFID Location Tracking and Asset Management

Modern RFID systems don’t just know what inventory you have, they know where it is. That expensive item that went missing? The RFID inventory system can tell you the last time it was scanned and its exact location.

Inventory Analytics and Demand Forecasting

Advanced inventory management systems can analyze sales patterns and predict future demand, helping retailers optimize their purchasing decisions and reduce overstock situations through better inventory forecasting.

RFID Technology is Finally Accessible for Small Retailers

For years, RFID inventory management technology was available only to large retailers with massive budgets. RFID systems required complex integrations, expensive hardware, and dedicated IT staff to maintain.

That’s no longer the case. Modern RFID inventory solutions are designed specifically for small and medium retailers. They integrate seamlessly with existing POS systems and inventory management software, require minimal training, and can be implemented without disrupting daily operations.

The RFID hardware has become more affordable and reliable. The inventory management software is cloud-based and user-friendly. The implementation process is streamlined and supported. The barriers that kept automated inventory tracking out of reach for most retailers have largely disappeared.

Making the Transition to Automated Inventory Management

Retailers considering the move from manual to automated inventory management often worry about the transition process. The concerns are understandable: Will RFID implementation disrupt operations? How long will it take staff to learn the new inventory system? What if something goes wrong?

The reality is that modern RFID implementations are designed to minimize disruption. Most retailers can run both manual and automated inventory systems in parallel during the transition, gradually shifting from manual processes as confidence in the new RFID system builds. Staff training on inventory management software typically takes days, not weeks. And the benefits of real-time inventory tracking become apparent almost immediately.

TRANSFORMATION TIMELINE: Most retailers see ROI within 3-6 months of implementing RFID inventory management.

The first time you complete an inventory audit in 30 minutes instead of 8 hours using RFID technology, the value becomes crystal clear. The first time you can confidently tell a customer “yes, we have that in stock” without having to physically check thanks to real-time inventory visibility, you understand the customer experience improvement. The first time you avoid a stock-out because your inventory management system alerted you to low inventory levels, you see the revenue protection.

The Cost of Staying Behind on Inventory Technology

Perhaps the most important question isn’t whether you can afford to modernize your retail inventory management. It’s whether you can afford not to implement better inventory control.

Every day you continue with manual processes, your competitors who have modernized with RFID inventory systems gain ground. They serve customers more efficiently, make better purchasing decisions with real-time inventory data, and operate with lower costs. The competitive gap widens over time.

Modern customers have been trained by Amazon and other online retailers to expect accurate inventory information and real-time stock levels. When you can’t meet those expectations with reliable inventory tracking, you lose credibility and sales. The cost of disappointed customers compounds over time.

Staff frustration with inefficient manual inventory processes leads to higher turnover. Finding and training retail employees is expensive and time-consuming. Inventory management systems that make jobs easier help retain good people.

The Path Forward to Modern Inventory Management

The dirty secret of retail isn’t that we’re all still counting by hand. It’s that we don’t have to be. Modern RFID inventory management is available, proven, and accessible.

The RFID technology exists. It’s affordable. It’s proven. The only thing standing between your current manual processes and modern automated inventory tracking is the decision to move forward.

That decision becomes easier when you calculate the true cost of your current manual inventory processes. Add up the labor hours, the lost sales, the emergency shipping costs, the overstock carrying costs, and the opportunity costs of staff time. Compare that to the cost of a modern RFID inventory management system.

For most retailers, the return on investment from automated inventory tracking is measured in months, not years. The system pays for itself quickly through time savings, improved inventory accuracy, and better decision-making capabilities with real-time data.

Frequently Asked Questions

Q: How long does RFID implementation take? A: Most retailers are operational within 2-4 weeks, with full optimization achieved in 30-60 days.

Q: Will RFID work with our existing POS system? A: Modern RFID solutions integrate seamlessly with most POS systems including Shopify, Square, and others.

Q: What’s the typical ROI timeline? A: Most retailers see positive ROI within 3-6 months through labor savings and improved accuracy.

Q: Do we need to replace all our current systems? A: No. RFID systems are designed to complement and enhance your existing retail infrastructure.

Your Next Step Toward Better Inventory Control

If you’re ready to stop counting by hand and start managing inventory like a modern retailer with RFID technology, the first step is understanding exactly where you stand today. How accurate is your current inventory tracking? How much time are you really spending on manual inventory processes? What are the hidden costs you might not have calculated?

Simple RFID offers a comprehensive Inventory Accuracy Assessment that helps retailers understand their current inventory management situation and identify the biggest opportunities for improvement. This assessment examines your existing processes, calculates your true costs, and provides a roadmap for modernization with RFID inventory systems.

The retail industry’s dirty secret doesn’t have to be your secret anymore. Modern inventory management with RFID technology isn’t just possible – it’s essential for competing in today’s market where customers expect real-time inventory accuracy and seamless shopping experiences.

TAKE ACTION TODAY: Join hundreds of retailers who have modernized their inventory management and gained competitive advantage.

Ready to modernize your retail inventory management? Download our free Inventory Accuracy Assessment to discover exactly where your operations stand and get a personalized roadmap for moving beyond manual counting to automated RFID inventory tracking.

Related Resources: