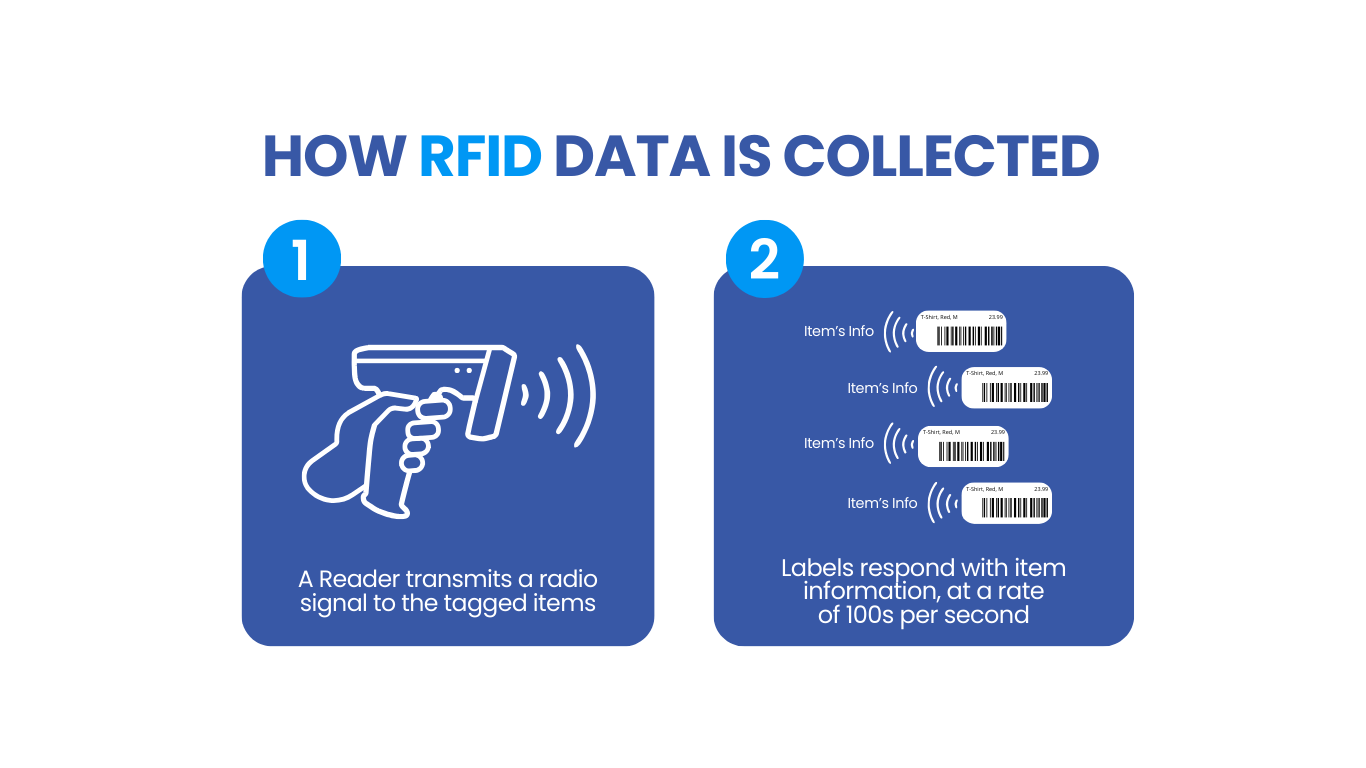

Accurate inventory counts prevent overselling, stockouts & provide visibility to all on-hand items.

Better visibility promotes better decision making, boosting sales & minimizing unnecessary costs.

Real-time visibility across all locations radically enhances logistics, sales & fulfillment processes.

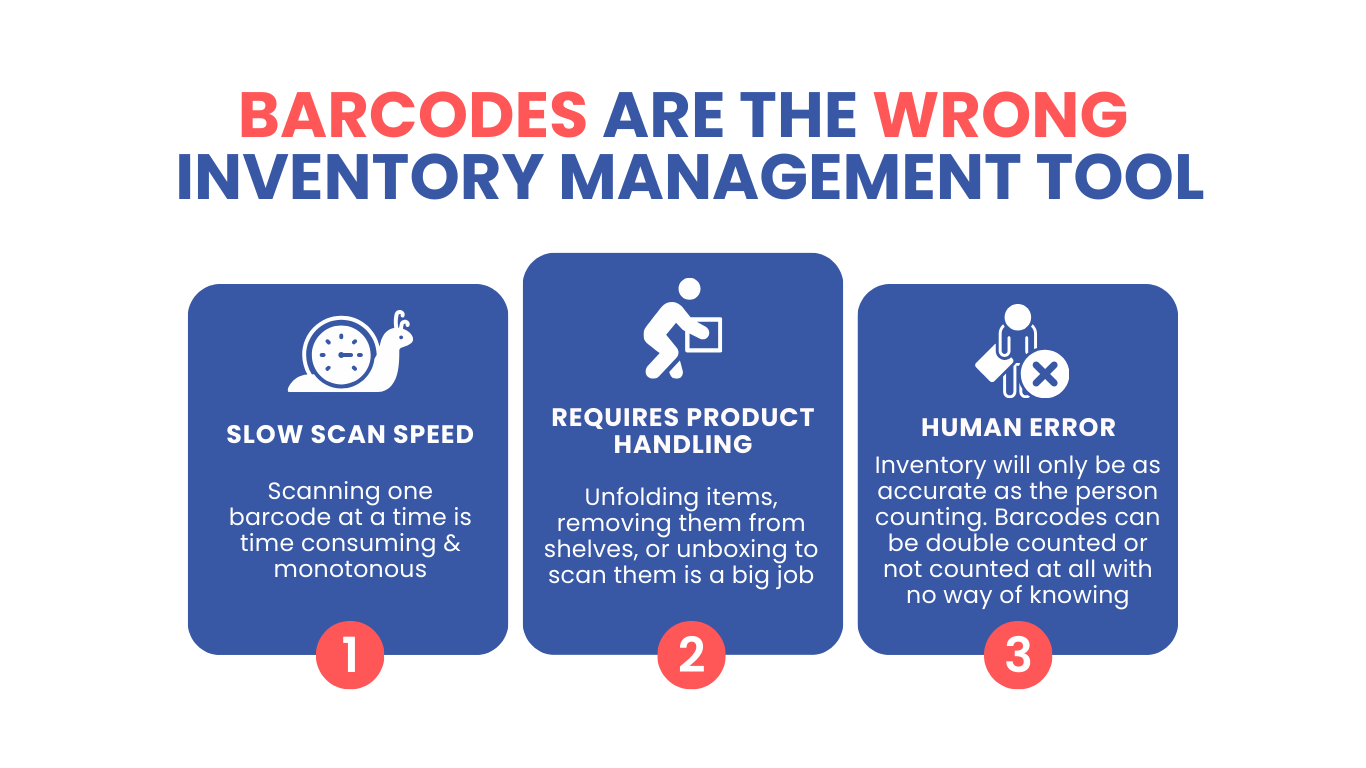

Is it difficult to track inventory volume & movement in-store or across multiple locations?

Are audits rare & difficult to accomplish, requiring extra employees & late hours?

Do employees waste precious time looking for missing items on a daily basis?

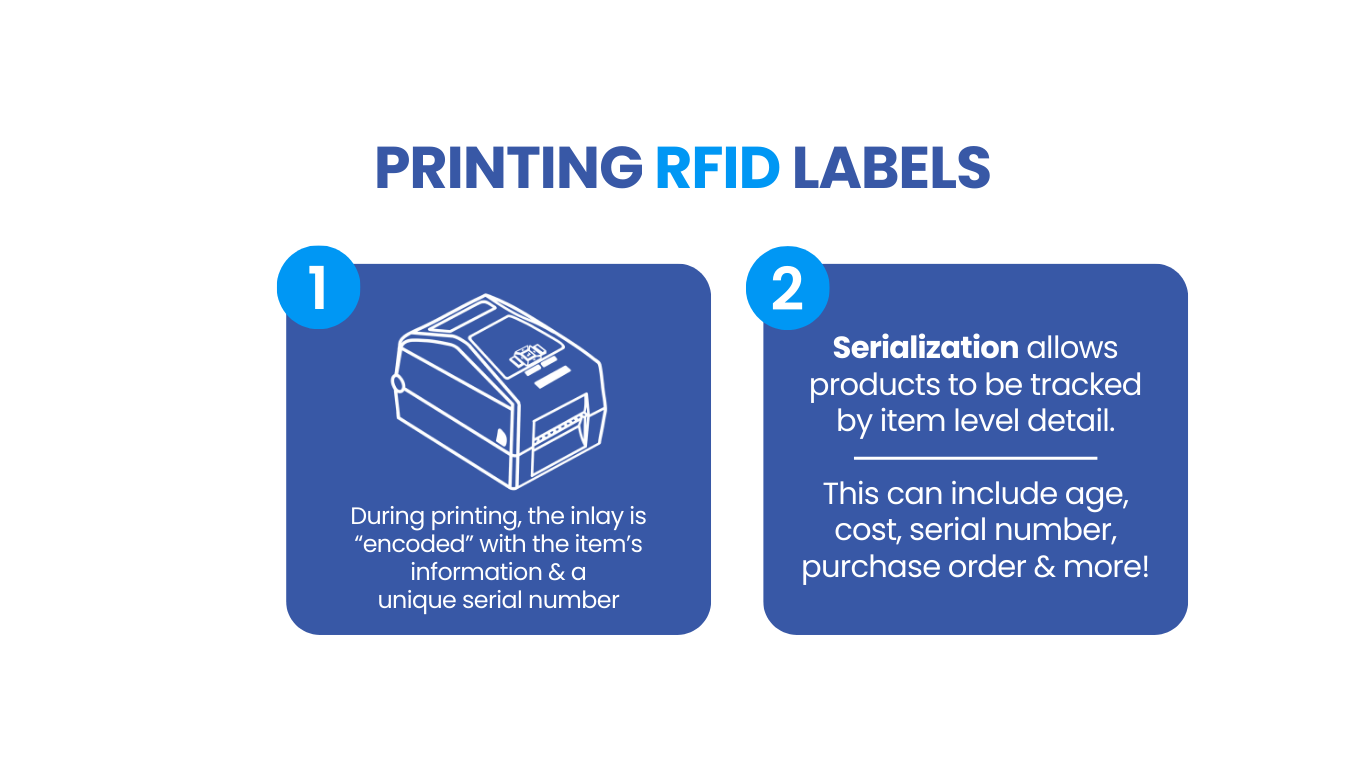

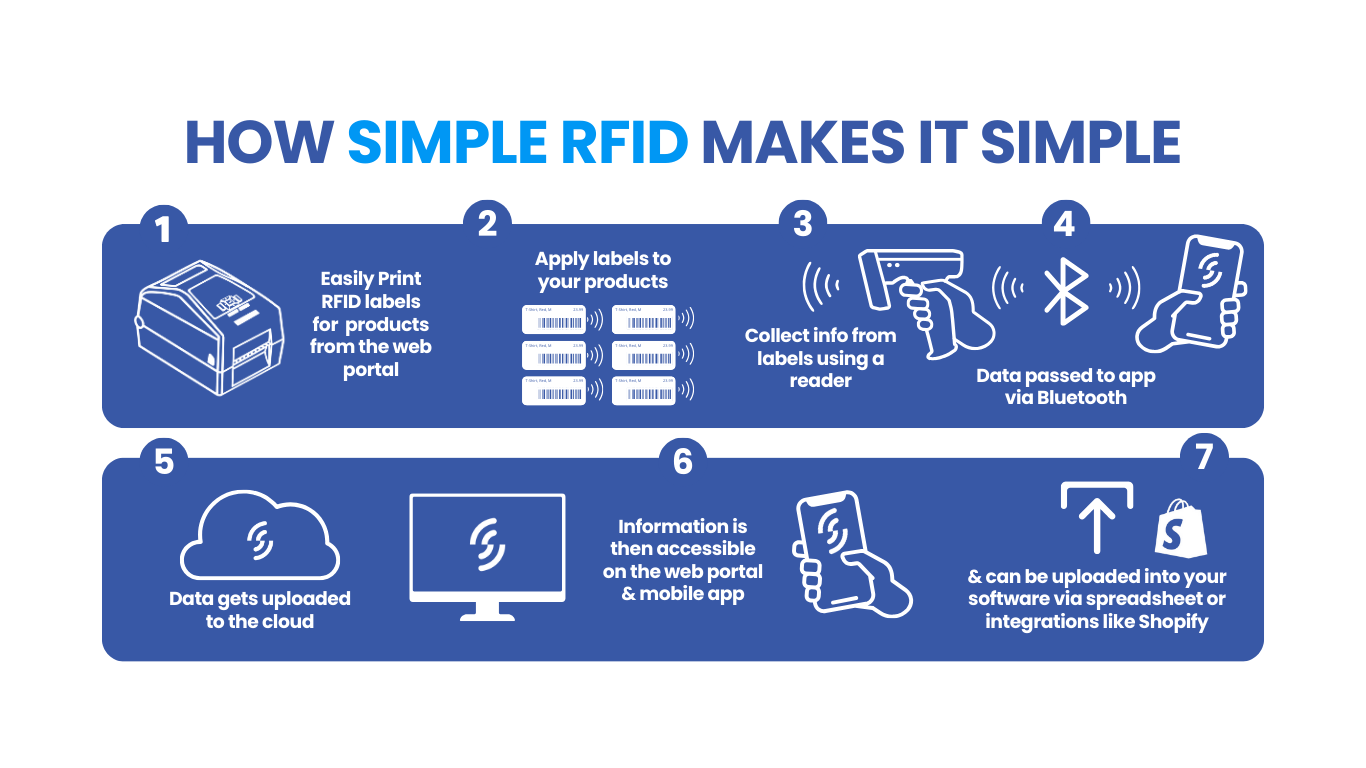

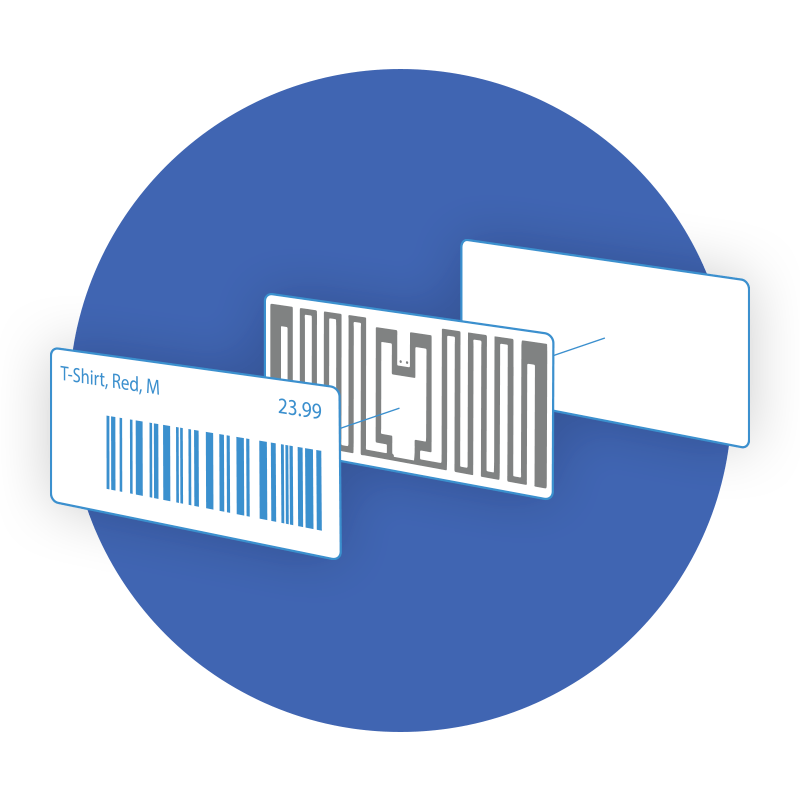

We sell industry-leading RFID printers, readers & high-quality labels & tags. Because of this, we streamline & expedite the adoption of the technology for our clients so they can benefit as quickly as possible.

Schedule time to discuss your RFID goals and objectives

Connect your printer to begin printing & tagging.

Leverage real-time inventory data to transform sales & operations.

“We used to spend 4 hrs doing inventory & now it only takes 15 mins! It is so efficient, makes auditing easy & it has helped with ordering.”

“Simple RFID help us realize how overstocked we are on items & understocked on others. We will easily save over $10-$20k this year…It’s a lifesaver. I used to have 12 pants in a size we never sell.. our point of sale system count was off so bad.”

“Fully satisfied & 100% confident… I have been able to streamline the operations of our organization … Amazing group of people to work with.”

“…nothing but impressed. It has greatly improved our inventory visibility, quality control & shipping accuracy. Incredible product!”

© Copyright 2024, Simple RFID, All Rights Reserved

134 N 200 E Suite 103, St. George, UT 84770 | info@simplerfid.com | 844-637-2464 | Privacy Policy

Want to receive push notifications for all major on-site activities?